The content below is a mirror of http://www.dalmotorsports.com/cars.asp. I did not author the content. I'm just providing it here since the original site does not seem to be up much of the time.

First I want to thank everyone who has contributed to this information; race teams, friends, news groups and my own R&D by product failure or success. I’ve listed topics in no particular order, other then thinking through the car from front to rear. None of the opinions within this document should be considered or used without personally assuming full responsibility of the potential consequences related your actions or use of knowledge.

Use at your own risk

The NSX community is unique; it’s made up of a high percentage of active car enthusiasts. I frequent other groups because of other interests, and have found that most of them are not as strong. Be grateful that we have a place like Prime that is so active you can almost consider it live, rather then needing to wait weeks or even months for answers or parts. I’m writing this because I want to give back to the community what I learned. My Race partner Vaughn Duarte shares this sentiment and has encouraged me to write this. It took a considerable amount of time to recall, review and write, so try not to get offended as this only needs to be a guideline of my opinions… and if yours are as strong, you can draw your own.

[NOTE: this document contains information about the DAL Motorsports Grand-Am Cup NSXs and the RacerXtream World Challenge Racing NSX. Both cars and series follow a totally separate set of rules. As not to be confused, we have tried to note as often as possible what areas apply to just one series/car.]

The front and rear bumper skins do not need the heavy metal crash bumpers for structural stability or mounting. (For racing only, and then this still assumes personal risk) Weight is the enemy of a good performing car. Even if you’re under weight in class, a rule of thumb is to whenever possible keep the weight between the wheels and as low as possible. I have witnessed scenarios where this metal structure caused harm. If removed, the front and rear bumpers are soft and collapsible to light love taps by a competitor, virtually un-noticeable… keeping the bumpers you literally increase the length of the car and taps result in a spin. In a race the metal doesn’t move back easily from a tire or radiator. If you stop 6 inches after the wall, your bumper will permanently push the frame 5 of those inches… with no bumper nothing hard gets permanently relocated. It’s arguable that I’m talking a fine line, and on the other hand I can imagine many scenarios where a bumper could help protect the car, but most of those scenarios would put me out of a race anyway. I also consider the safety angle, but I’m in it to win… and you don’t see GTS cars or F1 cars putting big heavy bumpers on because the sport is dangerous. Something to note: an aluminum rear bumper replacement exists as an OEM part number.

Ride

height

is an important challenge that plays a critical role

in the handling ability of the NSX. Lowering the

center of gravity on any car will aid its handling

ability, but some adjustments must be made to

restore Hondas intended suspension design.

When

lowered, the rear tire’s increase in negative camber

and

the toe arm rotates to a less then optimal angle

that produces what’s called “Bump steer”. This is

simply defined as; when the tire bumps up under the

load of lets say a turn, the hub attached to the

tire rotates further from the point that the toe arm

is linked to, so it turns the wheel similar to a

steering arm. In the rear the toe link is toward the

back of the car, and will develop additional toe out

as the tire bumps further. This is not a good thing,

you want a car to keep its optimal settings, and the

NSX likes a toe-in condition. The answer is to shim

the toe arm near level, and where you get the least

bump steer during usable suspension travel. When

lowering, the front wheels lose their ability to get

the negative camber they need, so you will have to

buy the Comptech camber kit. Our class requires 17”

rims and a spec tire. The car looked like an off

road truck(left picture), and we were far from

getting down to legal ride height. The problem was

two fold. We are limited to -3 deg camber so

lowering the car to legal

ride height meant rubbing the inside wheel well and

fender. In search of a

When

lowered, the rear tire’s increase in negative camber

and

the toe arm rotates to a less then optimal angle

that produces what’s called “Bump steer”. This is

simply defined as; when the tire bumps up under the

load of lets say a turn, the hub attached to the

tire rotates further from the point that the toe arm

is linked to, so it turns the wheel similar to a

steering arm. In the rear the toe link is toward the

back of the car, and will develop additional toe out

as the tire bumps further. This is not a good thing,

you want a car to keep its optimal settings, and the

NSX likes a toe-in condition. The answer is to shim

the toe arm near level, and where you get the least

bump steer during usable suspension travel. When

lowering, the front wheels lose their ability to get

the negative camber they need, so you will have to

buy the Comptech camber kit. Our class requires 17”

rims and a spec tire. The car looked like an off

road truck(left picture), and we were far from

getting down to legal ride height. The problem was

two fold. We are limited to -3 deg camber so

lowering the car to legal

ride height meant rubbing the inside wheel well and

fender. In search of a

solution,

other then sectioning the NSX into a Trans-Am race

car, Vaughn had an epiphany. He knew that our

problems included a couple of issues: a) Our ride

height was too high because we couldn’t get the car

lower with the 17”, and b) Our ABS was not as

accurate because we were using oversized wheels/tires(discussed

next).

He knew that the early stock NSX came with 15”

wheels and with them we wouldn’t have the two

issues… but we also knew the stock wheel did not

allow the contact patch(width) we needed. We

subsequently stumbled onto a miracle. The Touring

class had a 15” rim with

our spec tire (That measures exactly the same height

as OE but also gave us the width of the 17”). We

covertly tested this combination in a regional event

at Barber. We had something… without even fixing the

alignment the car was noticeably better handling.

Armed with the fact that the Cadillac team was

allowed to pay Hoosier enough money to make them a

special 18” tire (While the rest of the class had to

run 17’s), Pete Halsmer lobbied our request to allow

the 15” rim and tire. The handling dynamic on the

car is now incredible. Note; we don’t need to use

the lower lip spoiler.

solution,

other then sectioning the NSX into a Trans-Am race

car, Vaughn had an epiphany. He knew that our

problems included a couple of issues: a) Our ride

height was too high because we couldn’t get the car

lower with the 17”, and b) Our ABS was not as

accurate because we were using oversized wheels/tires(discussed

next).

He knew that the early stock NSX came with 15”

wheels and with them we wouldn’t have the two

issues… but we also knew the stock wheel did not

allow the contact patch(width) we needed. We

subsequently stumbled onto a miracle. The Touring

class had a 15” rim with

our spec tire (That measures exactly the same height

as OE but also gave us the width of the 17”). We

covertly tested this combination in a regional event

at Barber. We had something… without even fixing the

alignment the car was noticeably better handling.

Armed with the fact that the Cadillac team was

allowed to pay Hoosier enough money to make them a

special 18” tire (While the rest of the class had to

run 17’s), Pete Halsmer lobbied our request to allow

the 15” rim and tire. The handling dynamic on the

car is now incredible. Note; we don’t need to use

the lower lip spoiler.

Tire/rims are critical on the NSX because the ABS system is one of the best production based designs. The ABS system is a simple design that makes complex adjustments based on both assumptions and feedback from your wheel sensors. When one or more tires stop rotating by a specific programmed percentage, the system reacts to control the braking faster and better then most of us. Now, depending on the percentage of speed differentiation, it will time or control at different rates as needed. This is a simplified explanation of what it does, but will help explain many of the wrecked NSX’s at track events. If you buy aftermarket rims and tires that don’t perfectly fit the originally designed ratios from front rolling radius to rear radius, then the ABS brain already sees a percentage of variation even when grip is perfect. It will first react too early because if it was designed to react at let’s say 5% wheel speed variation, and your rolling radius is already off by 3%, then it will be reacting at only a 2% variation in traction. It then takes control and makes adjustments based on the tire’s it thinks is on the car. Brake coefficient of friction, and tire traction also contribute to the ABS getting confused, but this scenario is not your typical street car. Self programmable ABS systems exist for race cars, but they are expensive. Large rims are cool, but be happy with your super light 15’s in front… DAL Motorsports uses SSR Competition wheels which are only 8 lbs. And un-sprung rotating weight is the worst place to have weight. On a large percentage of the televised race cars you will see 3-part BBS style rims that look very heavy. The reason for this is that in any racing and especially at the pro level you get a lot of rubbing and bumping. The lower cost 1-part wheels like the ones we use will bend very easy. The BBS wheels look heavy because they are, or at least the part you see. The center section is likely magnesium and the outer is a thinner and lighter aluminum. Ultimately they are nearly the same overall weight, but the 3-part rim is much stronger.

Compliance

is best defined as rubber bushings flexing and

compressing when put under a heavy load like

cornering. The negative result is that all your

perfect alignment settings flex to less then perfect

because of this rubber. The rubber is there to

absorb bumps so the driver doesn’t fell like they

are in a junk box, but the rubber doesn’t belong in

a race car (Get in one… they sound

like rattle boxes). I will say that the NSX is

stiffer then most, but eliminating this compliance can do wonders for

your handling. We have 16 suspension locations that

fit this compliance category. Comptech is marketing

the 4 most important locations. The rear beam and

the vertical compliance lock. I’m going to start

with the vertical compliance lock on the front

suspension; the part is designed to stop this NSX

unique assembly from rotating. If you read the hard

cover NSX book this assembly is described as a

feature that improves braking by counteracting the

toe out compliance by producing toe in. You see, the

NSX also has another unique suspension design by not

only incorporating Non-compliant ball joints where

the “A” arm connects to the wheel hub, they also use

ball joints where the front of the A arm connects to

the frame. This eliminates all but one compliance

joint on each arm. Under heavy braking the front

tires want to push back and use up all the rubber

compliance. Since this compliance is only on the

rear of the upper and lower A arms (where it

connects to the frame), the tire wants to toe out as

the front side of the arm stays stationary. The NSX

featured vertical compliance rotates the tire back

in to minimize the differentiation. So one might say

that it may be counter productive to lock one area

without the other. (More on this later) In the rear

both sides of the A arms have compliance, in

addition to the toe arm. The Marketed Non-compliant

rear beams give less compliance, but are not fully

Non-compliant. They use urethane that is harder in

durometer then rubber, so it flexes less =

less-compliant rear beam. Most compliant locations

move spherically, not just rotationally. They rotate

and twist because they are on different planes.

Because of this spherical motion, the harder the

rubber, the more it will bind the suspension from

working properly… that’s as bad as having

compliance. Now just the rear beam shouldn’t bind

your suspension, but a job worth doing is a job

worth doing right. On a race car all of the

compliance points need to be replaced. On dedicated

race cars all of these suspension points are either

uni-ball joints, heims, or spherical bearings. It

takes a lot of engineering over 100 parts and $4000

to make an NSX non compliant. But the results are

jaw dropping. Note: Be sure to check your rear ball

joints for play or slop. If you have play, they

should be replaced for better handling.

but eliminating this compliance can do wonders for

your handling. We have 16 suspension locations that

fit this compliance category. Comptech is marketing

the 4 most important locations. The rear beam and

the vertical compliance lock. I’m going to start

with the vertical compliance lock on the front

suspension; the part is designed to stop this NSX

unique assembly from rotating. If you read the hard

cover NSX book this assembly is described as a

feature that improves braking by counteracting the

toe out compliance by producing toe in. You see, the

NSX also has another unique suspension design by not

only incorporating Non-compliant ball joints where

the “A” arm connects to the wheel hub, they also use

ball joints where the front of the A arm connects to

the frame. This eliminates all but one compliance

joint on each arm. Under heavy braking the front

tires want to push back and use up all the rubber

compliance. Since this compliance is only on the

rear of the upper and lower A arms (where it

connects to the frame), the tire wants to toe out as

the front side of the arm stays stationary. The NSX

featured vertical compliance rotates the tire back

in to minimize the differentiation. So one might say

that it may be counter productive to lock one area

without the other. (More on this later) In the rear

both sides of the A arms have compliance, in

addition to the toe arm. The Marketed Non-compliant

rear beams give less compliance, but are not fully

Non-compliant. They use urethane that is harder in

durometer then rubber, so it flexes less =

less-compliant rear beam. Most compliant locations

move spherically, not just rotationally. They rotate

and twist because they are on different planes.

Because of this spherical motion, the harder the

rubber, the more it will bind the suspension from

working properly… that’s as bad as having

compliance. Now just the rear beam shouldn’t bind

your suspension, but a job worth doing is a job

worth doing right. On a race car all of the

compliance points need to be replaced. On dedicated

race cars all of these suspension points are either

uni-ball joints, heims, or spherical bearings. It

takes a lot of engineering over 100 parts and $4000

to make an NSX non compliant. But the results are

jaw dropping. Note: Be sure to check your rear ball

joints for play or slop. If you have play, they

should be replaced for better handling.

Radiators When you’re trying to keep your engine revving between 7000 and 8000 RPM every possible second in a three hour race, the car is past its intended cooling capacity. The first thing we tried was playing with the thermostat, then we purchased a replacement radiator that claimed double the cooling capacity, we added oil coolers, fans, and even built an under-tray to reduce turbulence behind the radiator. Right now we are just under the danger zone with temperature. The best solution is a vented hood, but our class wont allow it. I’m not comfortable sticking with what we have. The way I see it, we have two more options A) I’m not to confident in the OE water pump, so I will try to increase flow with a secondary electric pump. B) I can still replace our radiator with a version where the manufacturer claims 4 to 6 times the cooling capacity. If you have the intentions to get an RTR nose, splitter/under tray, and hood, they have incorporated an angled radiator (Near 7” thick) for more down force. Note: Don’t trust your OE gauge, maybe not even your OE sending location. I’ve been nearly out of water because of a leaking head gasket, and the OE sender/gauge will only see the steam temperatures.

Sway Bar

We find that with good horse power the NSX wants a

lot of front sway bar. We also run no rear sway bar.

If your running a race car I suggest buying the

biggest front bar you can get your hands on, because

it’s not big enough. The largest bar I’ve seen on

the market is 1” or 1-1/8” bent bar, and I know of a

few one-off 1-1/4” bars made for racers (See DALI).

Realtime Racing used a 1-1/2” straight bar called a

knife edge bar (Because of the rotating

knife-edge arm that acts as adjustability).

These

bars are commonly used in Trans-Am cars, and are

welded to the front part of the roll cage. When I

first saw one, I didn’t even know what it was. A

straight bar has much more torsional rigidity then a

bent bar, and the thicker you go, its strength rises

incrementally. When building my World Challenge NSX,

Realtime advised me that 1-1/2 Inches wasn’t enough

(I’m sure a joke fits in here somewhere… anyway) so

I built one out of 1-3/4”. This is the WC car. The

Nickel bar running across the front of the car is

the sway bar. It’s held in place with a billet

bearing block and large stainless spherical

bearings. Needless to say again that the 1” bars on

the market are not enough, but buy and put on what

you can get.

These

bars are commonly used in Trans-Am cars, and are

welded to the front part of the roll cage. When I

first saw one, I didn’t even know what it was. A

straight bar has much more torsional rigidity then a

bent bar, and the thicker you go, its strength rises

incrementally. When building my World Challenge NSX,

Realtime advised me that 1-1/2 Inches wasn’t enough

(I’m sure a joke fits in here somewhere… anyway) so

I built one out of 1-3/4”. This is the WC car. The

Nickel bar running across the front of the car is

the sway bar. It’s held in place with a billet

bearing block and large stainless spherical

bearings. Needless to say again that the 1” bars on

the market are not enough, but buy and put on what

you can get.

Our Grand-Am class posed another problem; we could

only have a bar that fastened to the stock location.

More hours of Engineering- instead of using the

weaker bent bars, I relocated some components and

designed overcomplicated billet bearing blocks to

utilize a 1-1/4”

straight bar. The blocks house spherical bearings so

the bar doesn’t have any compliance loss, and won’t

bind under chassis flex. The ends are splined for

custom bent billet arms. The bars cost me about

$1300 in parts,

so

I’m not thinking it’s very marketable, but then

again winning is priceless to those of us addicts.

With all of the suspension

points and sway bar having bearings, I can jack the

front of the car off the ground and easily make the

opposite wheel rise as I lift one side. That’s how

it’s supposed to work, if you try this on a stock NSX with compliance resistance and paper clip thin

sway bar… it doesn’t move.

so

I’m not thinking it’s very marketable, but then

again winning is priceless to those of us addicts.

With all of the suspension

points and sway bar having bearings, I can jack the

front of the car off the ground and easily make the

opposite wheel rise as I lift one side. That’s how

it’s supposed to work, if you try this on a stock NSX with compliance resistance and paper clip thin

sway bar… it doesn’t move.

The picture to the left also shows the vertical

compliance lock

The picture to the left also shows the vertical

compliance lock

Brakes

are mysteriously good on the NSX, the reason I use

the word mysterious is that the fronts are single

sided dual piston with relatively small rotors, and

the rears are single piston. Compared to the

competition this is one of the worst combinations

(in theory). Many cars (Even cars like the RSX) have

dual sided pistons, 4 pistons, and larger rotors.

It’s a wonder we consider the brakes good? I think

it is related to the mid engine design, coupled with

the fact that we have a race level 4-channel ABS

system. Unfortunately when you start racing the car,

the weaknesses revile themselves. After you add

larger slicks, race pads, and higher speeds, it

becomes apparent that the NSX is lacking brake

potential! Partially due to the loss of a modern

crutch… the ABS system, and partially due to the

fact that our “wusy” brakes should have never felt

as good as they do.

If

your rules allow and you can afford it, see RTR for

a Bosch ABS system. I will add that one of the first

mistakes people make is to fit the largest brake

system they can find, 6 to 8 pistons with monster

diameter and wide rotors… many times with equal size

in the rear. Brake systems should be only as much as

you need for the worst of conditions, because the

brakes are one of the worst places to have weight.

In motorsports like NASCAR, they will change rotors

and brake

systems depending on what they need for that

particular track. This is more important then you

think. Dyno your car before and after a big brake

upgrade, and you will see a horsepower loss at the

wheels… and that’s only measuring the smaller rear

rotors. Were not all brake experts (I’m not either),

but if winning is more important then just racing,

you should consult an expert or fund the

experimentation yourself to get only as big as you

need. Back to racing- I find that when set-up for

the best handling, the NSX will want to lock the

rears first. You may be able to find a front to rear

pad combination that will change the bias in the

rear… if not, you will need to add (2) brake bias

levers in line for the dual channel rear brakes.

Fortunately the brake lines go right past the

driver’s seat on the inside of the car. Brake line

bias is the wrong way to adjust bias, a balance bar

is optimal, but that requires a complex addition of

dual masters. This eliminates the power assist,

requires bracketry, linkage, and a new way to

incorporate ABS. If you’re building a World class

car, and the rules allow this mod, it is

unavoidable. (If you’re that person, I can provide

billet brackets for Tilton dual masters w/balance

bar).

If

your rules allow and you can afford it, see RTR for

a Bosch ABS system. I will add that one of the first

mistakes people make is to fit the largest brake

system they can find, 6 to 8 pistons with monster

diameter and wide rotors… many times with equal size

in the rear. Brake systems should be only as much as

you need for the worst of conditions, because the

brakes are one of the worst places to have weight.

In motorsports like NASCAR, they will change rotors

and brake

systems depending on what they need for that

particular track. This is more important then you

think. Dyno your car before and after a big brake

upgrade, and you will see a horsepower loss at the

wheels… and that’s only measuring the smaller rear

rotors. Were not all brake experts (I’m not either),

but if winning is more important then just racing,

you should consult an expert or fund the

experimentation yourself to get only as big as you

need. Back to racing- I find that when set-up for

the best handling, the NSX will want to lock the

rears first. You may be able to find a front to rear

pad combination that will change the bias in the

rear… if not, you will need to add (2) brake bias

levers in line for the dual channel rear brakes.

Fortunately the brake lines go right past the

driver’s seat on the inside of the car. Brake line

bias is the wrong way to adjust bias, a balance bar

is optimal, but that requires a complex addition of

dual masters. This eliminates the power assist,

requires bracketry, linkage, and a new way to

incorporate ABS. If you’re building a World class

car, and the rules allow this mod, it is

unavoidable. (If you’re that person, I can provide

billet brackets for Tilton dual masters w/balance

bar).

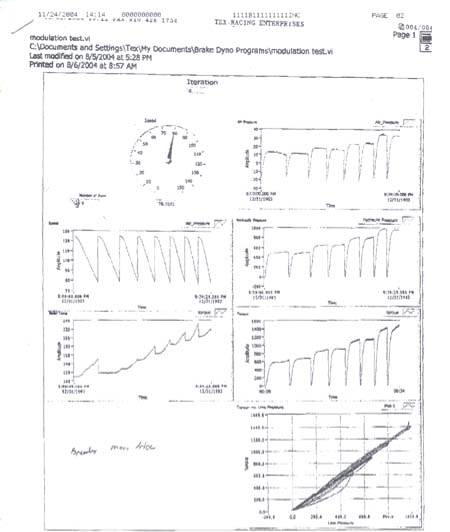

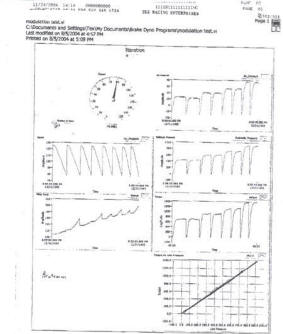

Another subject is Brake pads… The track is no place of OE brake pads. There are a lot of aftermarket pads that are better suited for autocross or tracking. DAL uses Cobalt Friction blue front with Hawk blue rear. The Cobalt’s are a better on the rotors than some aftermarket pads. Speaking of rotors- we can crack the familiar aftermarket rears in one race… don’t even think of using them in the front. Use OE, or even better a two part rotor like Stoptech with curved cooling veins. When you go to a race setup, investigate other rotor manufacturers with the same bolt patterns. I know a famous racer who doesn’t use his *Free* Brembo rotors (About $300 each), he pays near $800 each for Alcon rotors. Material, design, and treating are very important in a super brake system. Brakeman rotors are an in-between to Brembo and Alcon leaning closer to Alcon, and are at near Brembo prices. If allowed, carbon rotors are even better. Fluid- I use Motul if I don’t have heat issues and Castrol if I do. DAL uses ATE Super Blue Racing Fluid. Brake ducts are important in the front (Usually can’t get enough heat in the rear). You want to point the air in the center of the rotor, to be drawn out with the veins. Not an easy task, until you have a race car and can remove some things in the way, and add an under-tray for protection. Back to the ABS system- In a race car that allows ABS, unfortunately you must use it to be the most competitive (even if you need to add weight)! As mentioned earlier they are expensive $10,000 and up, but are unbelievable. When programmed right with good brakes, you can use both feet on the brake pedal as hard as you can, and slow before a turn as good as if you were trying. And if it rains, competitors won’t understand why you and the other ABS cars are lapping them. *Recent information: I’m looking at brake modulation test sheets from Tex Racing (They do more then 50% of the Winston cup cars). Their brake dyno runs from 125 to 80 mph consecutively and records speed, brake torque, air pressure, hydraulic pressure, and rotor temperature. The Lighter and less expensive Brake Man F4 caliper out performed the $2000 each Brembo GT monoblock caliper (Previously the industry standard for best) The F4 ran 30 degrees cooler, required 100lbs less line pressure (On average), made a flatter torque curve, and most important had a much more consistent torque vs. line pressure between runs.(this means less caliper flex)

Brembo monoblock Brake Man

A common misconception is that if you can lock-up

your brakes, you have as good of a brake setup as

you can get. That’s not a true statement- Here’s an

analogy; When using the heater controls in many cars

it’s difficult to get the setting from not being too

hot or too cold. But in many current cars you have

increased adjustability that makes it easier to get

what you want. Brakes are the same, all of them can

lock the wheels… the better ones have more

adjustability before they do lock. If you have two

knobs; Knob (A) representing OE or bad brakes,

(having) 3 clicks before full. Knob (B) a good

performance brake has 10 clicks before full. Think

of full as lock-up with your brakes. With knob (A)

you can go to click 2 before lock, but one click

more and your skidding. Knob (B) you can safely go

to click 8. That’s 4/5 braking capacity vs. 2/3

braking capacity. In addition to the higher

percentage of usable threshold, you have 2 clicks

before a locking condition, giving you a 50% larger

safety margin.

Mathematically you can get infinite variability

before lock-up, but using realistic technology we

have limited solutions to work with. I’m not sure if

most people know that lock-up is actually first due

to an imperfection of rotor surface, tire flat spot

or road surface variation. Your pressure threshold

can stay consistent until it hits a high, low, rough

or slippery spot. Now with the road surface or

tires… just avoid water, oil and flat spotting your

tires. But with brakes, the HP manufacturers go with

larger diameter rotors so they can benefit from

leverage, and don’t have to push as hard because of

being towards the center of rotation. They also

spread the clamping between two or more pistons. And

last, they float the rotors from the hubs so they

can absorb imperfections of the hub or the rotor

surface. All of these methods help miss the high

spot. More driver adjustability (Like mentioned in

the first paragraph) will also allow you as a driver

to closer flirt with that threshold. ABS technology

aids after the lock-up has already happened. A new

technology is a relief valve that absorbs spikes in

the brake line pressure from those high spots. Some

are experimenting with this now.

Clutch Street- I like the OE clutch for its mild manner. Note: if your reinstalling the OE clutch, it not only needs to be initialized, it first needs to be “loaded”. Initialization is the spring loaded release for proper seating. A new clutch is already loaded, so even most dealers don’t know to do this step. They typically install new clutches. This tip might describe why so many who installed good condition clutches had problems putting the trans in gear. One would assume their clutch was bad, and replacing it with new would solve their problem. The 1991 manual explains how to “load” the springs, but it didn’t clearly explain why.

Track car/Race- I like the Exedy single or

dual Cerametallic for its strong grip (It may be a

little aggressive for many streeters), low weight,

balance and long lasting. (Some have complained

about T/O bearing noise)

If weight and size is unlimited and you have

high horsepower, I would use a mini Tilton triple

disk. The track/race clutches are already borderline

for using the OE clutch master and slave, so I would

suggest replacing them if reliability is important.

For the Tilton you will need a new Tilton slave and

master. The slave is slick… it replaces the throw

out bearing and is easier to do trans swaps. The

master requires new bracketry and linkage. (If

you’re doing this expensive conversion, I have the

brackets. I also have the custom order Tilton part

numbers for the slave, flywheel, master and clutch)

Exedy Single w/flywheel

Exedy Dual w/light flywheel

Tilton Triple w/light flywheel

Roll-Cage

The NSX is state of the art in design and can only

be compared to exotic limited production cars like

some Ferrari’s. That’s not to say that other cars

like Porsches, or Corvettes aren’t as competitive or

even faster, but that’s only because of Horsepower

or aftermarket modifications. One of the features of

the NSX is the all aluminum chassis, frame, and

cockpit.

This

light weight design is

made up of extrusions, and formed aluminum sheet

welded together to create a strength far greater

then the sum of just one of its parts. The NSX is

one of the stiffest chassis sold, and one of the

contributors to it’s good handling characteristics.

Quoting something I read. An NSX is so ridged that

if you put it on 4 jack stands, it will rock because

the floor is likely not level enough. Though that

has since been proven, the NSX is not ridged enough

to fully support race conditions especially with

high horsepower… No car is. With this in mind, a

cage needs to be designed not just for safety, but

for chassis strength. Since your NSX is likely much

lighter then your weight requirements, add extra

reinforcement to improve rigidity. Especially in the

front. I wish I had the picture in mind to insert

here- It’s a straight-on shot of the Realtime NSX

coming out of a turn with good traction during a

race. If you look at the plane of the rear wing

compared to the twist of the roof and front nose,

you would think it was a top fuel drag car.

Supporting evidence would be the new NSX that

Realtime built for the 2003 season. Most of you have

never seen this car because it never made it to the

track, as Peter transitioned to Nissan. The cage in

this new NSX was nothing like the first car;

This

light weight design is

made up of extrusions, and formed aluminum sheet

welded together to create a strength far greater

then the sum of just one of its parts. The NSX is

one of the stiffest chassis sold, and one of the

contributors to it’s good handling characteristics.

Quoting something I read. An NSX is so ridged that

if you put it on 4 jack stands, it will rock because

the floor is likely not level enough. Though that

has since been proven, the NSX is not ridged enough

to fully support race conditions especially with

high horsepower… No car is. With this in mind, a

cage needs to be designed not just for safety, but

for chassis strength. Since your NSX is likely much

lighter then your weight requirements, add extra

reinforcement to improve rigidity. Especially in the

front. I wish I had the picture in mind to insert

here- It’s a straight-on shot of the Realtime NSX

coming out of a turn with good traction during a

race. If you look at the plane of the rear wing

compared to the twist of the roof and front nose,

you would think it was a top fuel drag car.

Supporting evidence would be the new NSX that

Realtime built for the 2003 season. Most of you have

never seen this car because it never made it to the

track, as Peter transitioned to Nissan. The cage in

this new NSX was nothing like the first car; its focus was similar to mine. (World Challenge NSX

pictured)

its focus was similar to mine. (World Challenge NSX

pictured)

Notice the braced tube; this is used as a jack point. If the tires are flat a jack won’t fit under the car, so we keep a steel insert in the pits, that can be put into this tube for jacking the car up.

Another benefit… that apparently happened during a race with Peter Cunningham as a driver- A competitor started pushing or “rubbing”, and this cage mounted device refused to move like the thin aluminum door and cut that competitors tire. This gives a new meaning to the saying “He rubbed me the wrong way”

A part I could supply to any future cage builder is

a bolt on plate kit. My cage fabricator told me that

it would cost me as much money to make all

the

mounting plates, as it would to build the cage.

So I measured and drafted professional looking

mounting plates that are laser cut. I put (4)

rectangular plates in the cockpit, with equal

thickness backing plates to sandwich through the

extruded frame rails. Some NSX’s have hole-sawed the

bottom of the frame and only bolt through thin

sheet. (I don’t believe this is safe or good for

performance from rigidity). The JGTC cars are

required to weld the cage to the car, so they use a

combination of bolts carbon fiber plating and epoxy

to get a chemical bond with the chassis. Our plates

for the (4) strut towers are also well thought out,

and can be ordered for OE style or Moton style

shocks. The front struts tie into (2) front frame

plates. All plates are pre-drilled for a perfect

fit. (See pictures under Sway bar (6)). Here’s a

picture showing the detail that went into the

external safety controls that we put on both sides

of the cars. Corner workers have complimented us on

this feature. The third component in this picture is

an external port for our data acquisition.

the

mounting plates, as it would to build the cage.

So I measured and drafted professional looking

mounting plates that are laser cut. I put (4)

rectangular plates in the cockpit, with equal

thickness backing plates to sandwich through the

extruded frame rails. Some NSX’s have hole-sawed the

bottom of the frame and only bolt through thin

sheet. (I don’t believe this is safe or good for

performance from rigidity). The JGTC cars are

required to weld the cage to the car, so they use a

combination of bolts carbon fiber plating and epoxy

to get a chemical bond with the chassis. Our plates

for the (4) strut towers are also well thought out,

and can be ordered for OE style or Moton style

shocks. The front struts tie into (2) front frame

plates. All plates are pre-drilled for a perfect

fit. (See pictures under Sway bar (6)). Here’s a

picture showing the detail that went into the

external safety controls that we put on both sides

of the cars. Corner workers have complimented us on

this feature. The third component in this picture is

an external port for our data acquisition.

Suspension- If you can afford them, Moton Triple or Quadruple adjustable shocks are the best. I can’t take credit for finding these, but I can tell you why the claim of best is more then opinion. I will start off by stating that more then 50 cars in the World Challenge use them. Truthfully many shocks can be adjusted to work equally, but the difference is what it takes to get that adjustment. Most shocks have a small range of adjustment within the good working range you need for a particular track or condition. Penske brand for instance is an icon in racing shocks. They can be adjusted like most others, but within a short range, beyond that they need to be disassembled, re-shimmed, and then checked on a shock dyno. The Motons creator who started with JRZ (The only other shock with this design), developed a valving using an adjustable orifice rather then shims and shim pressure. The end result allows you to fully tune your suspension, rather then just to the best place before re-valving. So simply… the Motons are better because they are adjustable in the real race world. I’m not Dale Earnhart Incorporated, and have many other things to tune in a short time. And if it rains, you can adjust further and faster then many of your competitors… If it rains during a race, they are dead in the water (While we can adjust while changing tires). Rumor has it that Evringham uses them to tune with, then dynos them on a full range shock dyno, so he can duplicate the valving in the shocks that everyone sees the cars racing with. Motons use spherical eyes at each end, so you will need conversion mounting brackets. I can supply these, along with the eyelet bushings.

Alignment- In the beginning I use to change toe for super speedways that favored long straights vs. tight road courses with lots of curves. But I systematically have proven to myself that the best overall performance for the NSX was to favor the handling vs. top speed. After all it is a handling car, and the alignment changes hardly affected top speed, but drastically effected handling. On a race car- Max out your caster (Max is most amount of angle), because max will increase your negative camber under turning conditions. Also Max out your negative camber… well this is relative to what numbers you can get. Even your average weekend warrior would benefit from –3 degrees in the front and rear. But if you start using offset ball joint bushings and offset spherical bearings, you will see gains all the way to as much as –6 degrees in the front. I must warn you… don’t get fooled by tire temps, or conflicting advice. Try it yourself. As you start going beyond –3 your insides will show high temps because of the straights, but if you take the angle back out to even the temps, you will be hurting your cornering ability. The skid pad will tell the truth. Toe- in the front I suggest 3/16” total toe out, and ¼” toe in at the rear.

Aero (World Challenge)

- A big rear wing with a true airfoil design is the

highest priority. The wing design will give down

force at lower

speeds,

and actually have less drag. Put it higher then the

roof, and extend it beyond the bumper

if

you can.

I would suggest the wing from RTR if you have high

HP. While you’re at it their trunk lid also gives

down force. Next, I would focus on getting the car

low especially in the front, and incorporate a

strong splitter (preferably a carbon fiber sandwich

honeycomb structure). If your splitter doesn’t

double as an under tray, that should be next for

extending the flat floor of the NSX.

if

you can.

I would suggest the wing from RTR if you have high

HP. While you’re at it their trunk lid also gives

down force. Next, I would focus on getting the car

low especially in the front, and incorporate a

strong splitter (preferably a carbon fiber sandwich

honeycomb structure). If your splitter doesn’t

double as an under tray, that should be next for

extending the flat floor of the NSX.

I also add a solid steel or aluminum plate (Depending on weight), as a further flat bottom extension under the gas tank. This adds additional safety and is the best place for weight. Angle it up towards the back for added down force. A rear angled diffuser would also be good, as the OE bumper is like a parachute without the OE muffler. A less obvious modification would be a vented hood and front nose combination for more down force. And the least obvious are side skirts with a large side extending lip for down force in the turns. Everything I just mentioned has been mastered by RTR, so that is where I would start for the splitter/under-tray, nose, side-skirts, trunk and rear wing. The fuel cell plate I can provide. I would try Science of Speed for the diffuser or rear wing if not Realtimes.

Fuel System-

Our stock NSX cell is better then any other OE cell

I have seen. It has hinged doors to trap fuel in a

small compartment

around

the fuel pump. This design is made to capture fuel

in the turns when the tank is low. Race cells are

made like this. We can drive past “E” on the gauge…

even in

race conditions. I have a championship SSC

Neon that starves above a 1/4 tank. If maximum fuel

level isn’t an issue, I would add fuel cell foam to

help minimize fuel sloshing (Not in the small hinged

compartment). This sloshing can get a race car

loose. For most applications I would suggest the HP

Walbro pump, unless you’re above 500 hp. At this

point I would use the Expensive Bosch pump. Not many

of the drag race pumps will handle continuous road

race duty. (They overheat) If you’re running more

then a single shot

of Nitrous, defiantly replace the fuel pump. This is

what happens to a piston when you

around

the fuel pump. This design is made to capture fuel

in the turns when the tank is low. Race cells are

made like this. We can drive past “E” on the gauge…

even in

race conditions. I have a championship SSC

Neon that starves above a 1/4 tank. If maximum fuel

level isn’t an issue, I would add fuel cell foam to

help minimize fuel sloshing (Not in the small hinged

compartment). This sloshing can get a race car

loose. For most applications I would suggest the HP

Walbro pump, unless you’re above 500 hp. At this

point I would use the Expensive Bosch pump. Not many

of the drag race pumps will handle continuous road

race duty. (They overheat) If you’re running more

then a single shot

of Nitrous, defiantly replace the fuel pump. This is

what happens to a piston when you

run

out of fuel capacity while using Nitrous (left

picture).

run

out of fuel capacity while using Nitrous (left

picture).

The WC car made big HP and could use as much as 25 gallons in a single race, so the stock 18ish gallons wouldn’t cut it… even if your class did allow stock. I developed a Kevlar design with all the best features that utilizes every inch and fits as much as 26 gallons. It’s fabricated from my drawings by the best in the business. (This cell would require the floor plate mentioned in Aero(12)). If you’re running High HP, use bigger fuel line. A twin pump design would decrease your chance of a DNF. You should cross over your fuel rails in more then one location, to insure even fuel delivery. Return to the tank through a quality regulator and use #8 line. Replace your injectors with 440’s even with minimal mods, go higher when needed. My favorite unleaded fuel that’s commercially available is Phillips B-42. I had a sponsor that funded a dyno test with all the unleaded fuels, the B-42 was best for detonation, and was tunable to make the best HP. It’s also inexpensive, but not likely at your local road course.

Engine Mounts-

Even the stock HP will eventually tear the OE engine

mount.

They

are a webbed rubber design that won’t handle much

abuse. I have seen

continuous exhaust cracks due to their

flexibility. You can easily make your own

polyurethane mounts, by purchasing a two part

polyurethane, sealing one side with good duct tape,

level them before pouring, and let them dry. The

tape will come off easy, and you can trim any

overflow with a razorblade. Don’t forget to put

something down to protect from runoff. Etching the

OE rubber before pouring would be a good idea, but

not necessary as the liquid urethane will seep and

harden on both sides of the mount. We can do this

for you, but it would cost about $200 a set because

of time and about $100 in materials.

They

are a webbed rubber design that won’t handle much

abuse. I have seen

continuous exhaust cracks due to their

flexibility. You can easily make your own

polyurethane mounts, by purchasing a two part

polyurethane, sealing one side with good duct tape,

level them before pouring, and let them dry. The

tape will come off easy, and you can trim any

overflow with a razorblade. Don’t forget to put

something down to protect from runoff. Etching the

OE rubber before pouring would be a good idea, but

not necessary as the liquid urethane will seep and

harden on both sides of the mount. We can do this

for you, but it would cost about $200 a set because

of time and about $100 in materials.

Oil Conditioning-

Honda uses a specific viscosity oil that works best

for street driving, you may have noticed that they

suggest a thicker oil in California and in warmer

climates. In a racing engine, especially road

racing, your temps sustain high heat (As high as

350+ degrees) that thins your oil beyond what the

factory wants. You may have noticed your pressure

decreasing as your engine gets hotter (This is

normal). But when racing the oil can get so thin

that you risk it’s ability to maintain the

pressure/volume needed to do it’s job as designed.

Many of your engine parts never touch metal to

metal, they actually ride on a thin layer of liquid

oil, since this oil is incompressible, all you need

is a thin amount provided the volume and pressure

stay constant. When the oil thins, it flows out of

its restricting gaps too fast. If the oil isn’t able

to reach one of the bearing surfaces for whatever

reason, the metal to metal will burn before you can

say Oh Shi?. This is why any performance engine

builder will suggest 20/50 (ie. Valvoline Racing

Oils) or other synthetic 15/50. When up to operating

temperature it will be the viscosity the engine was

designed for. Note: always bring your engine up to

operating temperature before putting it under heavy

load. I didn’t always have the patients to wait, and

would fool myself into thinking the engine is warm

already, so I use a

unique sending unit in my radiator (A trick I got

from a veteran racer), the sending unit senses 6

pounds of pressure before the light (I keep on my

dash) goes off. See, water temp isn’t always a good

indicator that it’s ok to push the engine, but

you’re OK when the water actually gets the engine

and system hot enough to raise the pressure.

Note:

The OE oil pressure gauge is another one that I

wouldn’t trust. The temperature of your oil can also

climb way above your water temperature, and 20/50

can even get too thin. The other side effect is that

the hot oil helps over heat the water cooling

system. You should defiantly add an oil cooler. My

favorite choice is an 85,000 BTU water to oil

cooler. It’s both expensive, and will require custom

engine adapters. But it’s the only cooler that will

allow me to over cool, so I can adjust the

temperature depending on track conditions. See, too

cool will rob you of power, and too hot will do the

same. My target is around 250 degrees. The cooler

I’m using is the only water to oil cooler that has

the capacity to handle the NSX. And any air to oil

cooler wouldn’t allow me extreme adjustability.

Note:

The OE oil pressure gauge is another one that I

wouldn’t trust. The temperature of your oil can also

climb way above your water temperature, and 20/50

can even get too thin. The other side effect is that

the hot oil helps over heat the water cooling

system. You should defiantly add an oil cooler. My

favorite choice is an 85,000 BTU water to oil

cooler. It’s both expensive, and will require custom

engine adapters. But it’s the only cooler that will

allow me to over cool, so I can adjust the

temperature depending on track conditions. See, too

cool will rob you of power, and too hot will do the

same. My target is around 250 degrees. The cooler

I’m using is the only water to oil cooler that has

the capacity to handle the NSX. And any air to oil

cooler wouldn’t allow me extreme adjustability.

I would also highly suggest an Accusump to any NSX’er that tracks their car. When in sustained V-tech, most of your oil is in the engine and not in the pan. If the oil pick-up in the pan starves for a second… your engine is done. Preventative insurance (Especially needed if you track High banked ovals) get an Accusump! An Accusump holds more oil (our cars have 3-qt versions), the oil is pressurized by the stock oil pump against a piston and spring (Like a syringe). If the pump stops pushing for even multiple seconds, the spring will push back to keep your oil flowing with pressure. Genius design. Shutting a valve before shutting the engine, will allow you to maintain pressure in the canister, so that you can open the valve and pre pressurize before starting your engine. With our oil cooler, #12 lines, Accusump, and filter adaptor with Knob adjustable oil flow rate (For cooling), gives us near a 10 quart oil system. Another strong suggestion, but one I can hardly suggest unless your engine is out anyway, is aftermarket oil gears. A known weak link in engines running in the upper RPM range. We also use a hinged baffled oil pan, but that’s probably overkill. Unfortunately our oil system with AN plumbing and block adaptors costs near $4000. I would also use synthetic oil or race proven non-synthetic (ie. Valvoline VR1), however if building a fresh engine first break it in with non-synthetic oil. That’s how good synthetic oils work! they wont allow the rings to seat properly. Something else I do when I change pump gears, is add a .060” (or less) washer on the inside of the spring loaded piston that governs the oil pressure. The washer acts as a shim to slightly increase your oil pressure about 10lbs. Be sure to use a washer that is nearly an exact fit.

Rerouting- A lot of stock NSXs have had problems with oil spitting out of the rear valve cover under heavy tracking at high RPM. Honda acknowledged this design flaw by redesigning the rear valve cover on the later cars. Some have never experienced this... some don't drive hard enough. I have permanently solved the problem on all of the cars including our race cars. The problem- (Likely accentuated by your new driving capabilities or style) In V-tech your oil is routed to the heads (Via solenoid valve) to facilitate the hydro lock of the rockers below the more aggressive cam lobe. This design requires massive amounts of oil that leaks profusely like the oil pressure at the crank bearings. The rear head actually fills with oil (The reason why an Accusump is needed for extended V-tech and high G turns... Not enough left in the pan) When the rear cover is full, high-G right hand turns push pure oil out the tube... Not what a breather was designed for. In the OE design, minimal oil is routed directly back into the engine at the throttle body and burned. A breather can be bolted horizontally on the ledge behind the drivers head (In the engine compartment)

You have two options (One takes longer then the other)

(Short)

Plug the rear valve cover oil out

Plug the hole in the intake hose before the throttle body

Plug the vacuum line (engine side) going to the front valve cover PCV. (discard PCV)

Run a hose from the front valve cover (PCV hole) to the new catch can. Preferably as high as possible.

I promise, no one needs to re think this, it will work.

(Long-This one requires valve cove removal, but is the best solution)

Drill the side of the front valve cover (Similar location as the hole on the rear valve cover)

Remove the pressed in tube sticking out of the rear valve cover (It’s pressed in)

Tap both covers for AN fittings

Run a hose from one valve cover to the other

Plug the hole in the intake hose before the throttle body

Plug the vacuum line (engine side) going to the front valve cover PCV. (discard PCV)

Run a hose from the front valve cover (PCV hole) to the new catch can. Preferably as high as possible

Both variations would be more professional if the valve covers were removed for tapping to AN fittings. The PCV hole will require disassembly and reassembly of the internal baffle in order to use a bulk head fitting. Note- fittings can not be welded, as the valve covers are Magnesium.

Transmission- Use a

6-speed if you can afford one. The more gears you

can get in the same ratio span, the less likely you

are to have a track with a turn where you can’t get

the right RPM. At one time I contemplated having

gears made spanning 2nd gear to just over 4th gear,

using all 6 gears. That would be optimal short of the $85,000 cost wanted to build

the custom sequential for the NSX. The other

advantage the 6-speed has over the 5-speed is the

Differential. The 5- speed has an adjustable limited

slip, that needs to be adjusted very high to put the

power to the pavement. Unfortunately because of

trans temps (Up to 450 degrees), the high clutch

pressure set at the beginning of a race compared to

the measurement at the end of a race is usually

half. In addition, the high clutch pressure is not

good for the turns. The 6-speed has a helical

differential, that helically puts more pressure on

the clutches as you put the power down. The benefit

is that you can set the clutch pressure less then

stock for great cornering, and when the car has

traction off the corner the horsepower will push the

clutches tighter then you can adjust the 5-speed.

The best of both worlds. The adaptation of a 6-speed

in a 5-speed race car is easy, use a toggle switch

for reverse. The shifter is the same, the solenoid

in the trans differentiates between 6th or reverse.

The spline count is the same on both, but the spline

length is shorter on the 6-speed, so the dual disk

clutch wont work in the 6-speed without a main shaft

replacement. Temperature along with angle cut

gearing is a weak transmission link in high

horsepower cars (If I made gears I would make them

straight cut for racing, but they would be loud).

Angle cut gears put pressure rotationally and

linearly… they push sideways and because of this

they break.

be optimal short of the $85,000 cost wanted to build

the custom sequential for the NSX. The other

advantage the 6-speed has over the 5-speed is the

Differential. The 5- speed has an adjustable limited

slip, that needs to be adjusted very high to put the

power to the pavement. Unfortunately because of

trans temps (Up to 450 degrees), the high clutch

pressure set at the beginning of a race compared to

the measurement at the end of a race is usually

half. In addition, the high clutch pressure is not

good for the turns. The 6-speed has a helical

differential, that helically puts more pressure on

the clutches as you put the power down. The benefit

is that you can set the clutch pressure less then

stock for great cornering, and when the car has

traction off the corner the horsepower will push the

clutches tighter then you can adjust the 5-speed.

The best of both worlds. The adaptation of a 6-speed

in a 5-speed race car is easy, use a toggle switch

for reverse. The shifter is the same, the solenoid

in the trans differentiates between 6th or reverse.

The spline count is the same on both, but the spline

length is shorter on the 6-speed, so the dual disk

clutch wont work in the 6-speed without a main shaft

replacement. Temperature along with angle cut

gearing is a weak transmission link in high

horsepower cars (If I made gears I would make them

straight cut for racing, but they would be loud).

Angle cut gears put pressure rotationally and

linearly… they push sideways and because of this

they break.

In the WC car, and soon to be in our Cup cars, we

put a large air to oil cooler with a fan (In the

back of the trunk). When the oil gets over heated the clutches act different

and consistency is important in road racing. To

utilize the stock transmission oil pump, you need a

complicated adaptor because the oil goes in and out

the same hole in the trans.

the oil gets over heated the clutches act different

and consistency is important in road racing. To

utilize the stock transmission oil pump, you need a

complicated adaptor because the oil goes in and out

the same hole in the trans.

Notes: If you do run a 5-speed… the 6-speed dif can

be modified to fit. Also, if I needed to pick one

set of gears between, stock, short gears, or a

combination with the three common sets of ring and

pinions; I would run the short gear set with the OE

ring and pinion. It has had the best average gearing

for the tracks you will encounter. This combination

is far better for road racing then OE, and if you’re

driving on the street it will still have the same

final drive ratio. I’m told that the aftermarket

ring and pinions are less durable then the OE when

used with high horsepower. The short gears even your

ratios and bring them down from 2nd to 4th. 1st and

5th stay the same. The ring and pinions lower

everything, making 1st unusable, and you still have

the poor 2nd gear transition. A combination of short

gears and the R&P bring your gearing way too low.

Weight- It’s not too difficult to get the race NSX to 2300 or 2400 lbs (Like our cup car), but most race classes require a heavier weight then that. I still take the time to trim the NSX, so that I can add the weight where it will do the most good. Earlier I mentioned the Fuel cell protection plate that doubles as a flat floor for better (under car) aero. It actually has a third function; it fits the race rule for weight: Between the axels and as low as possible. So when I need to add weight, I use ¼” thick steel plate (or thicker) instead of aluminum. This is an optimal location for weight, the NSX is not your typical car that wants a 50/50 weight distribution. It is designed to be closer to 40/60 especially with high horsepower and class limiting tires. Many useless things get removed when building a race car like power seats and AC, they will make up the majority of the weight loss. One of the best places to go next is the rear hatch, it’s quite heavy and sits high on the car. I don’t suggest replacing the front windshield unless you plan to replace it twice per season, because they fog quickly from rock chips. The OE glass is actually not too heavy. Another trick that a veteran racer showed me, was to use good and thick foam tape around the window seat, and then use the tabs to hold the windshield in place. Windshield glue is very difficult when removing a windshield. The original thought was really quick replacement (We always keep one in the trailer), but you would be surprised how often I remove it now that it’s easy, for working on something in the dash. I would also work on removing most of the harness and electronics. You can easily get 50 lbs here, but you better know what your doing. If you’re building an all out race car with aftermarket engine management, you’re better off just starting with a Painless brand harness for the basics. I’ve heard of people striping and acid dipping their cars for weight reduction, but that’s more of a cheating technique for All Stock classes like SSB or Super stock drag cars. It’s also been suggested (By those who have done this in the past) this seriously compromises the structural stability of the chassis, as it dissolves the seam sealing and gluing that bond the inner panels. I don’t suggest it. You can however take the labor intensive time to chip away all of the brittle floor insulation and you can scrape off the undercoating. Put all of this material in the same garbage bag and weigh it… you will be surprised at the results. Another place to look is the flip up headlights (Have you ever lifted this assembly?) Unfortunately I’m not sure if a lightweight and low cost solution exists. I have drawings for the bracketry that hold my –40lb solution, but they are also labor intensive. (This may be an exaggeration, I never weighed them)

Air filter- I have heard that tests have been performed with various air filter styles, and none of them drastically out perform the OE box. In the same breath they say “and the K&N can allow more dirt”. Hogwash! I have personally seen minimal improvements with the K&N and even more with no filter at all. If your too lazy to wash and lube a race filter, then you should probably use the OE filter… I however need every horsepower I can get. As for the filter housings- of course you’re not going to see an improvement on a stationary chassis dyno, ram air designs need movement. The design I’m fond of is the Cantrell ram air. I’m too poor to afford a pit bike cost worth of air filter components, but I think you will get the majority of the gains by utilizing the OE box with the Cantrell ram air nozzle. My thought is that the air still has to go through the same size filter regardless of the box it’s in… it does look nice though. (DALI gives you the choice and sells it this way for us non Ferrari owners).

Throttle Bodies- These were a logical test, when I discovered that our 300 RWHP version of the stock 3.2 would draw a small amount of vacuum again at high rpm. This tells me that I have a restriction limiting optimal air flow. I tried removing the air filter and that didn’t solve it. I then spent 20+ minutes swapping out my throttle body with the beautifully machined unit I got from SOS. The 20+ minutes was due to using dyno supplied tools, and changing over some of the emission/cruse control parts from my race modified unit. I did see gains, but they were minimal. So minimal that it could easily be written off as a change in conditions due to the 20+ minutes. It also didn’t solve the mystery vacuum clue. This leaves three places that could be restricting optimal air flow; 1) The intake manifold 2) The head flow or 3) the valve train. The intake manifold is already improved and I doubt it’s restricting flow (I will cover this later). The heads also flow about 3% better within the stock specifications and the rules. For now I’m guessing the valve train. So this is my current project that will also be discussed later in this engine section. Though our 300 RWHP out of a stock spec engine is impressive, it’s far shy of the hp that my supercharger engines have made. I’m guessing the throttle body would be better suited for higher HP. I almost forgot to write about those cruse control components I mentioned earlier. On the side of the Throttle body is a stepper motor that has the ability to close the throttle plate even if your foot is planted on the floor. For a self demonstration have someone hold the throttle wide open (Engine off!) and reach in and push the throttle closed. You will see that its not directly attached to the throttle cable, it’s only spring loaded. This does close some on it’s own, so I remove this assembly and tig the throttle bell directly to the butterfly shaft. However, this assembly is what your throttle position sensor is attached to, luckily the NSX has two TPS’s. I extend my harness 6” or 8” to reach the other TPS on the lower left of the throttle body. I also remove the vacuum idle adjuster. New thought- Don’t forget to plug any vacuum lines.

Intake manifold- First

remove and plug the EGR, this is an emission

component that also helps heat the manifold in cold

conditions. Not needed or wanted in a race car, even

the smallest amount of Carbon Monoxide entering the

intake will reduce the burnable oxygen content and

reduce your power. The next item to go is the

butterfly assembly plate known as the variable

runner system. This vacuum controlled contraption

along with v-tech is an innovative concept that in

theory will give you both long and short intake

tracts for better high and low RPM horsepower.

Unfortunately when removed both high and low RPM

horsepower are improved. In trying to figure out

it’s intent, I believe Honda engineers implemented

this device for better drivability. Better

drivability is defined not only in terms of

reliability, or fuel mileage, it’s how smooth a car

functions or starts etc. This assembly may have also

played a roll in emissions. The reason for its

over-all performance loss is likely related to its

restrictive throttle plates that would

flow

less air then the manifold runners. In addition the

plate assembly is less then smooth and would surely

cause more turbulence then smooth runners. The

turbulence slows the potential air flow into the

combustion chamber. The other notable draw back is

that this device is vacuum controlled and not

designed for boost applications. Anyone with

aftermarket turbos or superchargers will benefit

from removal. It’s a simple modification:

flow

less air then the manifold runners. In addition the

plate assembly is less then smooth and would surely

cause more turbulence then smooth runners. The

turbulence slows the potential air flow into the

combustion chamber. The other notable draw back is

that this device is vacuum controlled and not

designed for boost applications. Anyone with

aftermarket turbos or superchargers will benefit

from removal. It’s a simple modification:

-Remove the intake manifold (The gaskets are

O-ringed and re-usable).

-Turn the manifold over and remove the nuts

retaining the belly of the manifold. (try not to

damage the paper based gaskets, it may be a good

idea to have new ones on hand)

-Slide the Variable runner assembly off the studs

(Protect the gasket here also)

-Next remove all the studs. (A stud puller will work

best for potential reusing them in the future, but a

pipe wrench, vice grips, or channel locks will work.

-Now cut one of the gaskets so that it only makes an

outer ring to seal the belly pan without the runner

assembly.

-Measure for the length of bolts you will need in

each location to fasten the belly without the runner

assembly. -Take one of the studs and go to the

hardware store to buy exactly what you need. (They

are obviously metric- 6mm if I remember)

-Now assemble using some Honda bond, vacuum leaks

cause many problems especially with Nitrous.

-Then re-install the manifold, and anything else you

removed.

One step further but will require heavier tooling,

is to remove the divider wall on the inside of the

manifold. Be sure to smooth out all of the

transitions. This combination will maximize your

stock manifold. If porting is allowed you can port

match and smooth out the runners. I have been

threatening to make a sheet metal manifold… even

started the drawings. Maybe soon.

If Nitrous is your thing, the threaded boss for

holding the throttle body strain relief is a good

permanent location for a single fogger nozzle. If

you want to go big and don’t mind destroying an

intake manifold, the EGR ports act as a great

location for a direct port nitrous system. (You will

however need to mill the top off the manifold).

Don’t forget to plug any vacuum lines.

Balancer- I’m not sure

if this issue has been previously addressed, but I

have seen many harmonic balancer failures with other

NSX’s, and one of our Cup cars. Some engines are

internally balanced and some use the balancer to

counterweight the rotating assembly of the pistons,

rods and crank. Externally balanced engines need a

balancer. Internally balanced engines do not… hold

on and read more. The NSX is very well balanced from

Honda, but can be improved even more. On an

internally balanced engine like the NSX, the

balancer is not really a balancer and serves no

balancing function. It’s a pulley that’s weighted

like a flywheel. Flywheel weight is used to retain

load torque when on or off the throttle by utilizing

the inertia weight that wants to keep spinning. but

it takes more torque to get and keep that weight

spinning, thus sacrifices overall torque and

throttle response. Like a weed eater, it spins at

high RPM with little torque and would stop if it

encountered a finger sized twig. If you put a

flywheel weight on it, it would torque through that

twig… but may need more torque to get to speed. The

other purpose of the Balancer is to absorb harmonic

vibrations, tiny vibrations are measured in

frequency like sound, and all high rpm motors will

have increased activity at a specific frequency.

This harmonic frequency can do damage similar to the

results seen from detonation or cavitation, or

simply explained as more damage then seems feasible.

The way the balancer combats this Harmonic is by

insulating it with rubber. The balancer is made of

three parts; an outer and inner ring pressed

together with a thin

rubber

ring sandwiched between. Similar to cutting a brake

rotor with a band wrapped around it. This is a low

cost way of combating harmonics within our rpm

range. You can also minimize harmonics within this

range by doing a good job balancing… as Honda does.

I think this balancer feature is there as insurance

incase time or unknowns change the tolerance of the

internal balance. Many race engines eliminate this

weight as a performance gain, without problems. In

fact other factors such as a flywheel, clutch, or

driveshaft. Would have a greater impact then this

balancer. In any pro level race car, this balancer

would be replaced with something more reliable. I

can tell you that all of the Famous super NSX’s you

know have replaced or modified this part to be

solid. On the World Challenge engine, I turn down

the outer ring and the compliant rubber, machine a

high tolerance centering lip, tap holes and bolt an

off the shelf 8-rib Vortech pulley for a solid part.

rubber

ring sandwiched between. Similar to cutting a brake

rotor with a band wrapped around it. This is a low

cost way of combating harmonics within our rpm

range. You can also minimize harmonics within this

range by doing a good job balancing… as Honda does.

I think this balancer feature is there as insurance

incase time or unknowns change the tolerance of the

internal balance. Many race engines eliminate this

weight as a performance gain, without problems. In

fact other factors such as a flywheel, clutch, or

driveshaft. Would have a greater impact then this

balancer. In any pro level race car, this balancer

would be replaced with something more reliable. I

can tell you that all of the Famous super NSX’s you

know have replaced or modified this part to be

solid. On the World Challenge engine, I turn down

the outer ring and the compliant rubber, machine a

high tolerance centering lip, tap holes and bolt an

off the shelf 8-rib Vortech pulley for a solid part.

The reason- Heavy loads produce heat, heat melts the

rubber and causes the OE balancer to fail. The DAL

Motorsports cup engine had a balancer fail because

the alternator belt was tightened too much. It will

also eat up more horsepower. The tighter you go the

more heat you will produce. This is even more common

with the supercharged NSX’s everyone knows that when

the belt isn’t tight the SC slips and wont make as

much boost. I tend to only tighten the belt until it

stops making noise, and if supercharged I tighten

the belt while on the dyno, until I stop seeing a

rise in boost. I then feel how tight that is for the

next adjustment without a dyno. If you are doing

this without the dyno, lean towards too loose rather

then too tight. In fact tonight I need to make an

adjustment because my wife’s car is screeching at

start-up. Another way to increase your belt strength

is to go with more ribs. The cheapest way for

minimal improvement would be to use the Goodyear

Gatorback belt. They have a patent on a ribbed

design that gives more grip then the rest of the

brands. Most of the failures cause minimal damage;

Balancer, belt, and usually some cosmetic damage to

the front cover… But recently the balancer on Wei

Shen’s car (NSXCA President), separated in the

opposite direction towards the engine (Likely had

something to do being in a high G turn). Well it

went through the plastic front cover and made the

timing belt skip, bending valves, hurting pistons,

etc. I wont divulge the actual cost, but I will say

that if you are unfortunate this lesson can cost you

over $10,000 to fix it the right way.

Exhaust- The 3.0

manifolds are lacking compared to the 3.2 OE

headers. So get them while you can… In fact you will

see more then 2/3’s of the HP gain (on the dyno)

with the 3.2 manifolds compared to aftermarket

headers. Another interesting

note

is that many, if not all of the marketed headers for

the NSX are made by the same place. If you do go to

the 3.2 manifolds you will also need the remaining

3.2 exhaust or aftermarket components designed for a

3.2. Comptech use to sell conversion pipes, but I’m

not sure if they still do. The 3.2 manifolds are

welded internally and this weld restricts its flow.

My tip is to remove this bump with a die grinder and

clean them before installation. If racing, we can

make a good stainless steel exhaust that scavenges

from each bank. Not recommended for the street