Fathering a New Sports Car at Honda

In 1954, SOICHIRO HONDA proclaimed his intention to enter the Isle of Man TT race, the most prestigious motorcyde competition of its time. His company entered its first race in 1959 and came home with the team award. Two years later, Honda won both the 125 and 250 cc classes, firmly establishing itself as a world-class motorcycle manufacturer. This first motorcycle team victory started a rich collection of racing trophies which culminated about two decades later with Honda’s Formula One successes.

Honda’s racing experience and spirit, which few of its competitors can claim, has had a noticeable influence on its product policy. For example, the company values the difference between a sporty looking car and a real sports car. The sporty character of the former often remains skin deep; it is limited to a low-styled body and an oversized engine. Most of today’s flashy coupés are, indeed, beefed up derivatives of standard cars, from which they use the platform and most mechanical components. As Honda knows, to offer unique cornering and handling performance, a real sports car has to be conceived and built from the platform up.

Honda’s engineers dreamt of challenging Porsche, Ferrari, and a few exclusive manufacturers at the top end of the sports car market. Never mind the fact that such cars often remain exclusive toys for a limited number of affluent customers; the challenge was one of image and technology rather than economics.

The car embodying that challenge was to be the NSX. With its sleek, aluminum body and engine between the axles, Honda’s NSX has garnered rave reviews from auto magazines and drivers who can afford it. Reflecting its Formula One heritage, the car’s front wheels are smaller than the ones on the rear. The entire chassis, induding doors and front and rear decks, weighs only 452 pounds—44) percent less than a comparable steel chassis. On the road, the NSX’s performance inevitably brings smiles to the faces of potential customers.

Outsiders would probably assume that Honda deliberately planned the car from the start as a mid-engine, aluminum sports car. The reality. however, is far less simple. Even in a large and professionally run company like Honda, the planning of a car is not a linear process. It is strongly influenced by the results of many research projects and the testing of successive generations of experimental vehicles.

Transforming this complex process with its multitude of preliminary developments into a well balanced product constitutes a formidable management challenge. This was the task of the program manager, the real architect of the car concept, who gave the NSX its identity and brought it to the market very quickly. Even though the NSX is a special, low-volume car, the program management process by which it was born is very representative of what we would consider today as best practice in program management.

From Calculating Suspensions to Developing a Sports Car

The story of the NSX—a pilot process that produced a pilot car— begins with that of its project leader, Shigeru Uehara.

In September 1991, Shigeru Uehara felt as proud and happy as a new father. His “baby,” the NSX, launched less than a year before, was getting very favorable reviews from auto magazines and the most demanding car customers in the world. In spite of the economic recession, which had significantly reduced its market potential in the United States, the car was seen within Honda as a success. As a large project leader (LPL) within Honda R&D Company, the firm’s technology and new car development organization, Uehara had helped conceive, design, develop, and produce the car from start to finish, and its favorable reviews and customer feedback filled him with pride.

He was coming back from an extensive trip around the world to introduce the car to the press, dealers, and customers. For almost a year he had met specialists and customers, especially those who previously owned a Porsche or one of the sleek competing sports cars that the NSX targeted. He had been eager to find out what customers liked and disliked in the NSX, particularly by comparison with competing models. This would be critical for improving the new generation of sports cars which he would undoubtedly be asked to develop.

In accepting the overall management responsibility for the NSX, Uehara had joined the small but highly respected elite of car development LPLs, the powerful managers of Honda’s new car development programs. Although he had just been appointed executive chief engineer at the early age of 42, a very fast climb on Honda’s R&D ladder, he remained modest. He was first and foremost a car design architect, and looked forward to leading another new car program.

He knew that if his next car program was successful, his future would be assured. lie would one day become one of Honda’s influential representatives of automotive development (RADs) like his boss, Hiroo Watanabe. RADs are Honda’s highest-ranking product champions, sort of “super program managers,” although the company does not use that term. Supervising development programs for a family of cars, RADs have a very high degree of influence on the company’s product strategy and plan, and they sit at the automobile planning board together with Honda’s highest- ranking functional managers. Honda does not entrust the responsibility for a new car program like the NSX easily. Candidates must demonstrate their engineering excellence and breadth, and have a successful track record in project management. Uehara was no exception. Although he was only in his late thirties when he was appointed LPL for the NSX, he had an impressive career behind him with Honda R&D Company.

In 1971, at the age of 22, he had graduated as an automotive engineer and joined Honda’s Wako chassis engineering center. For several years he had worked in his academic specialty analytical engineering, immersing himself in the highly sophisticated discipline of modeling suspensions and steering systems.

Uehara had contributed his knowledge of steering systems to the Experimental Safety Vehicle program, an industry-wide collaborative research project in which he represented Honda. However, after a few years of work on analytical engineering, he had felt the need to work on real, new car development programs. At Honda, this meant writing new car specifications in his area of expertise: suspension, steering, and general vehicle handling. Later, after a prototype was built, he was involved in evaluating test results and solving development problems. Uehara was rapidly becoming one of Honda’s vehide handling experts, and he proved it by setting new handling performance standards for the Accord, Civic, and Prelude models. He accomplished this while continuing his more theoretical modeling work.

This ability to involve research engineers closely in new car development programs is one of the key strengths of Honda. Respecting individual talent and inclinations, the company will not automatically move research people into car development. Research managers continuously monitor the abilities and interests of their young engineers and encourage them to express their preferences. Those with a more theoretical bent are allowed to focus on analytical research projects. Those interested in applying their theoretical know-how to practical development programs are invited to join new car development teams in parallel to their research work. LJehara wanted to test his analytical abilities by seeing the results of the specifications he had developed, so he volunteered to work with a new car development program.

Research engineers typically work on research or car development projects for several years before becoming research project leader and then large research project leader (LRPL). Uehara’s first project management responsibility was to supervise the vehide handling part of a project aiming at developing an experimental vehicle concept with a flat engine mounted under the floor of the rear seat. In support of Honda’s famous 4M product philosophy— “man maximum; machine minimum”—the company was studying all possible alternatives to minimize the space devoted to the engine compartment. Honda hoped to achieve a breakthrough in car architecture. As one of the project leaders, Uehara was responsible for conceiving and evaluating the new concept from a road holding and cornering point of view.

The result of the project was promising. Although a mid-engine concept proved unsuitable for a family sedan, it offered superior road holding and cornering qualities. Uehara was convinced the idea would be ideally suited for a sports car.

Honda Research Company has traditionally granted a lot of freedom to its research project leaders, including that of proposing another project to pursue the promising results of previous research. Uehara was interested in further exploring the promising handling characteristics of the mid-engine concept. He proposed to his company’s research board that an experimental sports car prototype be developed incorporating the new mid-engine concept. Having demonstrated his project management skills, he was allowed to lead this new prototype project as a large research project leader. LRPL status is only granted to project leaders who have proven a dual ability as both a concept developer and a conductor of multifunctional efforts. Uehara’s new project would still remain a research project. However, he knew that experimental vehicle projects, if successful, can be translated into new car development programs. His boss, Hiroo Watanabe, was the living demonstration of that opportunity. The 50-mile-per-gallon experimental car project which he had led within research had given birth to two successive models: the small CRX sporty coupé and the successful new Civic. Watanabe had personally led the development program for the three-door Civic.

Uehara’s sports car project amply demonstrated the potential of the mid-engine concept. Incorporating the results of some of the 20 or so research projects that Honda had pursued in support of its 4M design philosophy, a first experimental prototype was built and successfully tested. One of these projects focused on the use of an aluminum body to reduce weight and thus gasoline consumption. The team could now envision the next step: developing a concept for a new sports car and then building a real prototype.

Defining a New Car Concept and Positioning

Uehara bad obviously thought a lot about his sports car idea. It had all started with the driving test of the experimental mid-engine vehicle. Although the prototype was quite high off the groi.md—its engine after all had to fit under the rear passenger seat—and very sensitive to side winds, it had an exceptional cornering ability.

Uehara knew that together with acceleration, the ability to follow sharp trajectories at high speeds was one of the key characteristics of a sports car. A high cornering performance gives the exhilarating feeling of grand prix racing, even when driving home on a suburban highway.

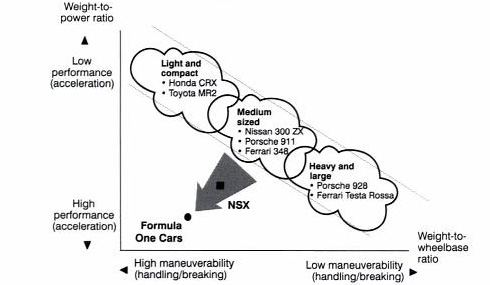

Knowing that a sports car performance is a function of both weight-to-power and weight-to-wheelbase ratios, Uchara tentatively positioned all existing sports cars on a curve along these two dimensions (see Exhibit 6.1). At one extreme of the curve were small, lightweight sports cars like Honda’s CRX or Toyota’s MR2. They had excellent cornering abilities but relatively low power and, therefore, suffered limited speed and acceleration. At the other extreme were the large sports cars such as Porsche’s 928 model or Ferrari’s Testa Rossa. Though very powerful and offering outstanding speed and acceleration, these cars sacrificed ease of driving. They were difficult to handle at high speed, requiring both special driving skills and a lot of physical strength. Yet, as Uehara observed, Ferrari and Porsche owners tended to be middle-aged men with neither the physical abilities nor the training of a race driver.

Exhibit 6.1 Positioning the NSX on the sports car map

Source Shigeru Uehara, Honda Research and Development Co., Ltd.

Uehara dreamed of designing a car that would combine Porsche 928 and Ferrari’s sense of raw power with the cornering of a small roadster. This looked like an impossible dream. The only car concept providing outstanding speed and exceptional handling was the Formula One, but it was not particularly easy to drive. Uehara felt his past work, first on the mid-engine vehicle project and then on his experimental sports prototype, provided a unique opportunity to offer high performance and driving ease. The mid- engine architecture that he had tested had been adopted by all Formula One manufacturers for its exceptional cornering performance. A light-weight, aluminum body would ensure an acceptably low weight/power ratio with a normal engine, thus delivering high acceleration performance.

Limiting the size of the engine was an important consideration for Uehara, who had the choice between a three-liter/six-cylinder engine and a five-liter/eight-cylinder engine. Many sports cars featured three-liter engines. A five-liter engine, which could be found on dream cars like the Lamborghini, would have too much torque and would make the car too difficult to handle. Uehara wanted to design a car providing the exhilarating driving impression of a Ferrari or Porsche, yet significantly cheaper (because of its smaller engine and larger production run) and much more forgiving on the road.

Uehara had to pull all these ideas together and demonstrate their feasibility, particularly the suitability of a three-liter engine. Convincing management was not easy, but the concept had a lot of appeal to Honda’s senior managers. If they accepted Uehara’s proposal for a second experimental vehicle project, they knew they were tentatively committing themselves to developing a new car, and that required a thorough strategic and economic justification.

Justifying a Car Program to Management

Honda Motor had not planned to develop a high-end sports car like the NSX. The concept had slowly emerged from a series of converging research projects on mid-engine architecture and aluminum body construction. This was a case where technical merit created the opportunity. As a large research project leader, Uehara had to convince management that his NSX product concept was not only strategically attractive but would also make economic sense as well.

He knew he could count on the help of Honda Motor’s product strategy and business strategy groups. These staff departments constantly monitor the results of research projects, checking them against the market, and help Large project leaders substantiate the business attractiveness of their proposal. The main dilemma for Uehara was one of positioning. What would be the ideal price/volume relationship? Was it economically feasible? Should Honda develop an exclusive, small volume car, or should it try to mass produce it at the risk of lowering its appeal? Like most Japanese manufacturers, Honda was interested in making its advanced technological concepts affordable to the greatest number of customers. Even though the car concept would be competitive with the fastest, most prestigious models from Porsche and Ferrari, Honda was not interested in developing a handcrafted collector’s car that would cost $100,000 or more. With the help of the product and business strategy groups, Uehara started by establishing a basic set of price/performance hypotheses and price/volume relationships. The optimum balance seemed to be a production volume of 25 cars per day with a retail price of about eight million yen, about $72,000.

The challenge was to prove the feasibility of producing a revolutionary aluminum car on a semi-industrial scale at a cost compatible with that target price. As a raw material, aluminum is more expensive than steel. To attain the same strength as steel, an aluminum body would have to be 1.4 times thicker than steel. A new manufacturing process would have to be developed to make the overall production cost-competitive and to reduce the initial investment cost in tooling and machinery to a level compahble with a low production scale. A research project, just completed, had established the feasibility of industrially pressing, welding, and painting aluminum. Having demonstrated the technical and economic feasibility of individual processes, Honda’s manufacturing engineers had to put them together in a coherent manufacturing system and plant layout.

Reflecting later on Honda’s NSX, a very high-ranking Volkswagen executive recognized that Honda’s superiority was probably not in its car concept or aluminum construction. “We can all do it!” he exclaimed. “What is unique is the fact that Honda should be able to make money on a car produced at a rate of 25 per day. In Europe. we know how to earn money at a production rate of 250 cars per day. . . . Some specialists, of course, know how to make cars by hand at a rate of five a day. We have to learn from Honda how to produce a car economically, i.e.: quasi-industrially, at a rate of 25 to 50 a day.” Five months after the start of the strategy study, Uehara could present to management a complete and economically viable proposal that would make his dream come true and turn his concept into a real car. The NSX program was born.

Conducting a New Car Development Program

With the blessing of Honda’s management, Uehara started his second prototype project, integrating all the elements of the future new car. The main objective of that research project was to demonstrate that the car would meet the desired performance profile with its three-liter engine. Once the prototype was developed and satisfactorily tested, Uehara was ready to design a real car. Management had to confirm its approval by officially starting a car development program, code named NSX, with Uehara as LPL.

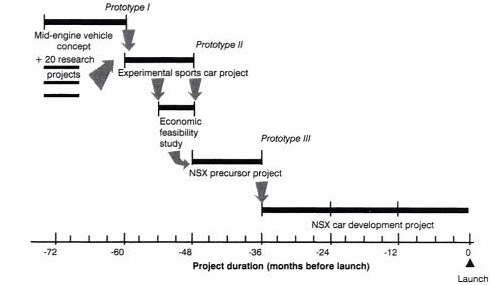

About three years had passed since the beginning of the mid- engine vehicle project, which had started it all. Three successive experimental prototypes had been developed and tested (see Exhibit 6.2). Once the NSX car development program started, it was going to take another three years.

Exhibit 6.2 From research to production: Development of Honda’s NSX

Source: Shigeru Uehara, Honda Research and Development Co., Ltd.

At Honda, not all large research project leaders become new car development large project leaders. Indeed, Honda usually con- a siders research projects and car development programs as very L) distinct efforts with different constraints and requiring different skills from their leaders. The NSX concept, though, had come from research. In addition, Uehara had amply demonstrated his vision and project management skills. He thus made the jump from research to car development and clearly won his appointment as LPL for the NSX. This change dramatically enlarged his authority and responsibilities.

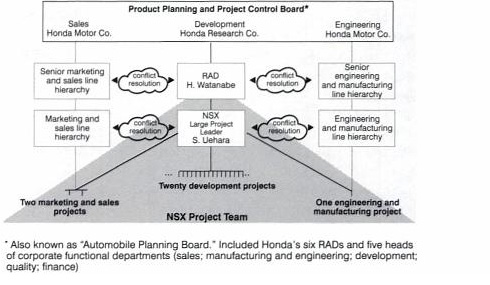

No longer limited to a few dozen research engineers, the team he would now be leading consisted of hundreds of engineers and technicians from all functions. The NSX program structure (see Exhibit 6.3) was typical of Honda’s new car development process. Even though the vehicle concept had been tested in a series of earlier prototype research projects, the car still needed to be styled, designed, developed, and tooled-up for production. Uehara could count on Honda’s functional hierarchy to help him structure the program. For each new car development programs an SED steering group—S for sales, E for engineering, and D for development—was put in place.

Exhibit 6.3 NSX project organization

Source: Hiroo Watanabe and Shigeru Uehara, Honda Research and Development Co., Ltd.

Working with the development group, Uehara set up about 20 development projects, each one under the official leadership of a project leader. He aLso ensured that parallel project teams would be created within sales (two projects) and engineering (one project) to support and implement the development effort.

As LPL, Uehara was the official conductor of the whole effort, even though he had no immediate hierarchical authority over anyone in his organization. At Honda, as in any other company. the coexistence of project and line organizations results in multiple tradeoffs and some conflicts. Functional project leaders, whether from development or engineering, report simultaneously to their functional line bosses as well as to the LPL. Honda’s two reporting lines officially carry an equal weight. Everything, therefore, hinges on functional line managers accepting the authority of the large project leader and on their willingness to cooperate.

This paradox is often poorly understood in Western companies. How can one exercise authority and also influence the behavior of a broad range of teams and people without any formal, hierarchical authority over them? This was not really an issue for Uehara, as he explained. “First, my appointment as LPL for the NSX program was done at the highest level within our management organization. This gave me a very high degree of credibility and influence. Line managers know that I have been entrusted with the overall responsibility. Their job is to help me carry this responsibility. Secondly, they also know that I have successfully led the various protects that led to the NSX. I know a lot about this program, which I have helped develop. They respect me because of my expertise and experience. . . . Finally, I have always had the entire support of Watanabe, my representative of automotive development at the automobile planning board. Whenever there was a conflict Ithati I couldn’t resolve, he was there to help me make the best decision for the success of the program. . . .”

Championing Products—The Role of the RAD

Hiroo Watanabe, one of Honda’s representatives of automotive development (RAD) at its automobile planning board, was the direct hierarchical supervisor of Uehara. He was officially in charge of all development programs involving big cars—those with six- cylinder engines. This included, among others, Honda’s Legend and Uehara’s NSX. With five colleagues. all RADs as well, Watanabe was responsible for overseeing the range of Honda cars from concept definition to withdrawal from the market. At any moment, each RAD supervised at least a couple of large project leaders like Uehara. They were Honda’s ultimate product champions, those who made the program management system work.

Watanabe acted as a kind of big brother and role model for Uehara. He had climbed high in Honda’s organization quickly through the program management route. Like Uehara, he had come from Honda’s R&D Company, of which he was a managing director. He had a long career behind him as program manager for new car development projects; he supervised the development of the Civic three-door, the Integra, and the Legend. His career straddled Honda’s two main car operating organizations: Honda R&D Company and Honda Motor Company, the manufacturing and sales arm of the firm. In his position, and like his other RAD colleagues, Watanabe was an officer in both companies.

As one of the managing directors of Honda R&D Company, Watanabe was the direct supervisor of large development programs like the NSX. He had the authority and power of a top functional line manager. Although Uehara claims that relatively few problems had to be solved at the RAD level, the group’s very presence gave authority and influence to the LPLs who reported to them.

By sitting with his RAD colleagues in Honda’s highest-level car strategy council, called the automobile planning board, Watanabe was in a strong position to influence and coordinate Honda’s product strategy and plan. This was particularly true since the reorganization, which put the most senior functional managers on the automobile planning board and thus tightened up the decision making process.

By appointing RADs and empowering them so visibly, management at Honda was clearly conveying a dual message: first, it gave a lot of authority and influence to a group of managers who represented the product side of the organization, therefore empowering indirectly its large project leaders vis-à-vis the line hierarchy. Second, it was opening an attractive new career route that could lead to very senior positions in the organization. This was a powerful incentive to attract the best possible talent to manage individual projects, and then large programs, as an alternative to running a functional department. Uehara was confident that his choice of the program management route had put his career on a trajectory that would take him quickly to the highest responsibilities within Honda.

Though sales of the NSX were disappointing—a fact blamed on the worldwide recession1—Honda management values the experience it gained from the project. The technical accomplishment of an all-aluminum car, NSX’s rapid product development, and the overwhelming response by car experts and well-heeled drivers bode well for future model announcements from a company that has mastered the difficult part of program management, the core process in product creation.

NOTES

Chapter 6 Empowering Program Managers

1. Honda’s NSX remains the centerpiece of the Acura showrooms where it is sold. In 1990, the first year the car was on the market, Honda sold 21,548 of them. Unfortunately, the second and third years saw the arrival of a worldwide recession and sales dropped. As Porsche, Lamborghim, and Ferrari similarly found, high-end sports cars head the list of items to be cut when times are tough. ...